Our Hardware Team

The If(Space) Invaders have one of the best hardware teams in the league working on new and innovative solutions to all of the problems we face on the playing field. We are able to quickly go from idea to prototype to finished design with the help of many technologies, along with good old cardboard and duck tape. All of our hardware team members have previous experience, with some being veterans to the team, and others coming from programs such as FIRST Lego League, where they solved similar problems with robots built entirely from LEGO. The If(Space) Invaders have one rule that we live by. WE DO THE WORK! All of the design and construction is done by kids on the team. Mentors don’t provide anything but suggestions and feedback.

Our Chassis

Starting from the ground up, we begin with our chassis. This was designed to give us as much space as possible to attach other elements of our robot, while also giving us the ability to move our robot quickly and precisely. We decided to use a drivetrain consisting of four wheels and two motors. The wheels on the front of the robot are specially designed OmniWheels, which are able to move both forwards and sideways. This means we can make turns easily, almost as if we were using tank treads. The wheels on the back of the robot are standard wheels with weather stripping added for traction. We did this because we needed to be able to get on to the balancing stone with our heavy robot, and because adding traction to the rear wheels is much easier than adopting a four-wheel drive system. This drivetrain has been super reliable for us, but one thing we are planning on improving in the next season is the speed. While it is fine for most purposes, we found that it was a little bit too slow for doing fast trips across the field.

Starting from the ground up, we begin with our chassis. This was designed to give us as much space as possible to attach other elements of our robot, while also giving us the ability to move our robot quickly and precisely. We decided to use a drivetrain consisting of four wheels and two motors. The wheels on the front of the robot are specially designed OmniWheels, which are able to move both forwards and sideways. This means we can make turns easily, almost as if we were using tank treads. The wheels on the back of the robot are standard wheels with weather stripping added for traction. We did this because we needed to be able to get on to the balancing stone with our heavy robot, and because adding traction to the rear wheels is much easier than adopting a four-wheel drive system. This drivetrain has been super reliable for us, but one thing we are planning on improving in the next season is the speed. While it is fine for most purposes, we found that it was a little bit too slow for doing fast trips across the field.

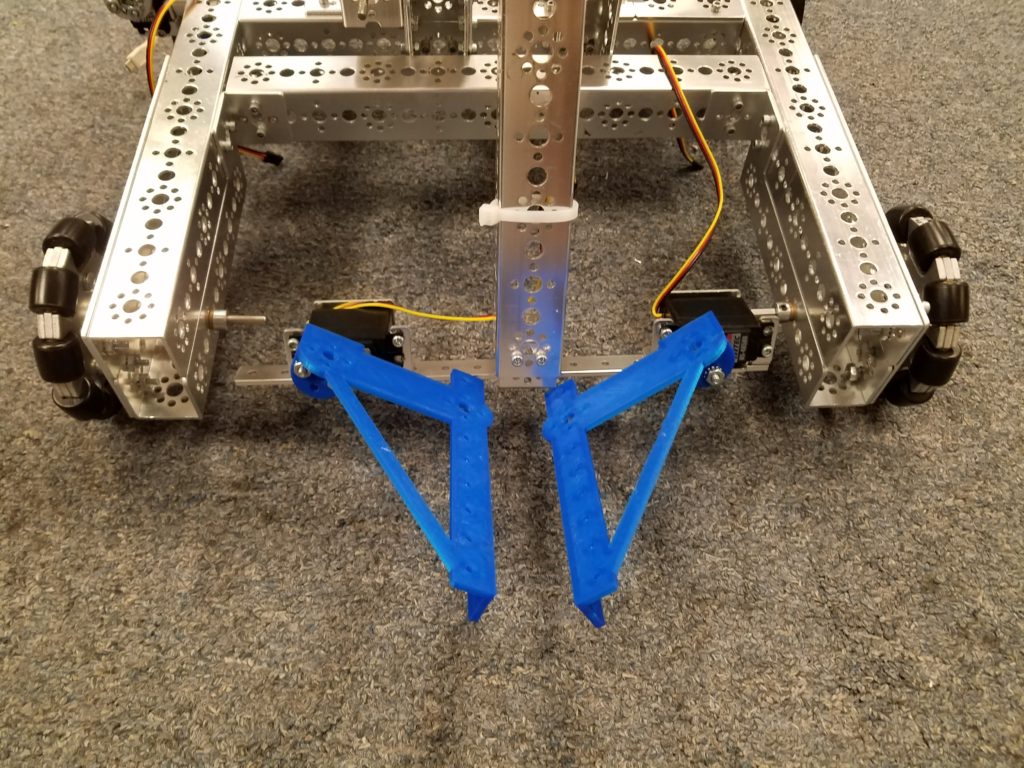

Our Glyph Gripper (v1)

Pictured above is the first design for a glyph gripper we tried. It was based around one arm that could pivot from the front of the robot to the back. The idea was that we could drive to our glyphs, pick them up with the grippers, flip the arm to the back of the robot, and then drive straight backwards into the cryptobox. We decided that it would be much faster and more efficient than having to turn our entire robot around each time we wanted to score. We designed custom 3d printed grippers for the end of the arm to try and reduce the weight on our motors. The problem we ran into with this design was that it was very complicated to gear our motor appropriately to handle the load of the arm and glyphs. If we attached the motor directly to the arm, there wasn’t enough power to lift it, but if we used a complex gearing system, it was far too slow to fit our needs, and it ended up being much faster to turn the entire robot. This was a good experiment for us, and it ended up leading us to our next design, which you can read about below.

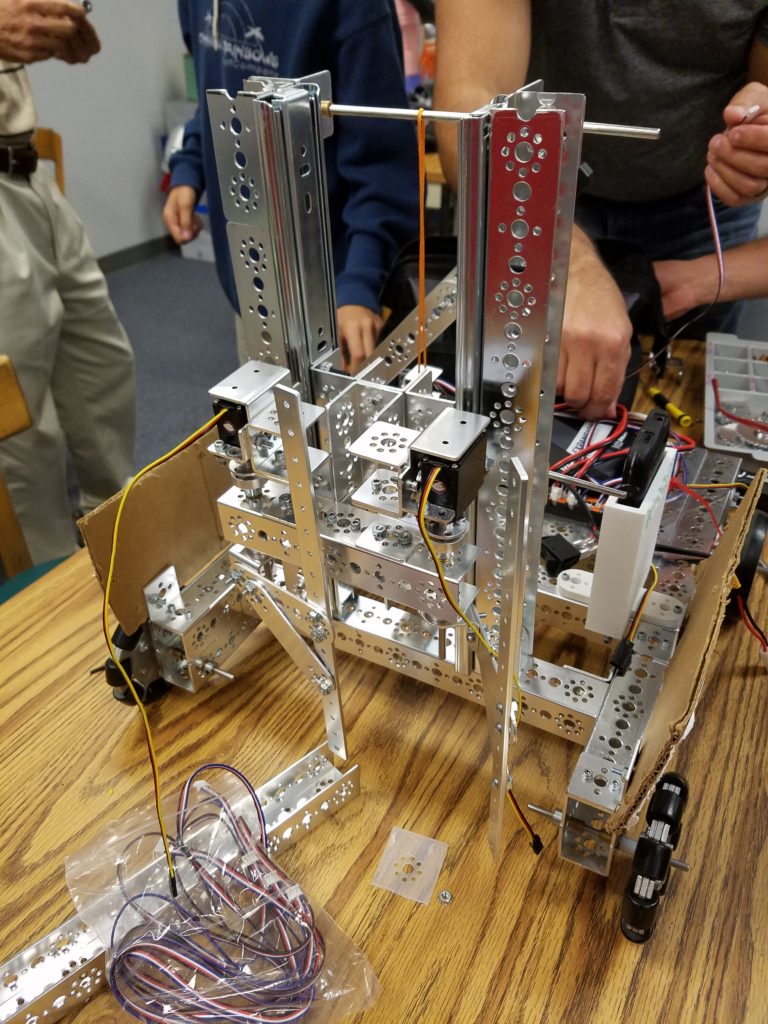

Our Glyph Grabber (v2)

After testing our arm-based design for placing the glyphs, we decided it was time to try something new. The first design wasn’t reliable enough or fast enough to compete in competitions, so we took a new approach entirely. This design is based on drawer slides. There are two mounted to both our robot chassis and the grabber mechanism itself, which allows it to lift vertically while staying stable. The actual grippers are made out of aluminum and driven by servos. Their height allows us to grab and place two glyphs at one time, doubling the number of cubes we can stack in a match. This mechanism is much easier and faster to operate than the arm we had previously, and it is also way more reliable.

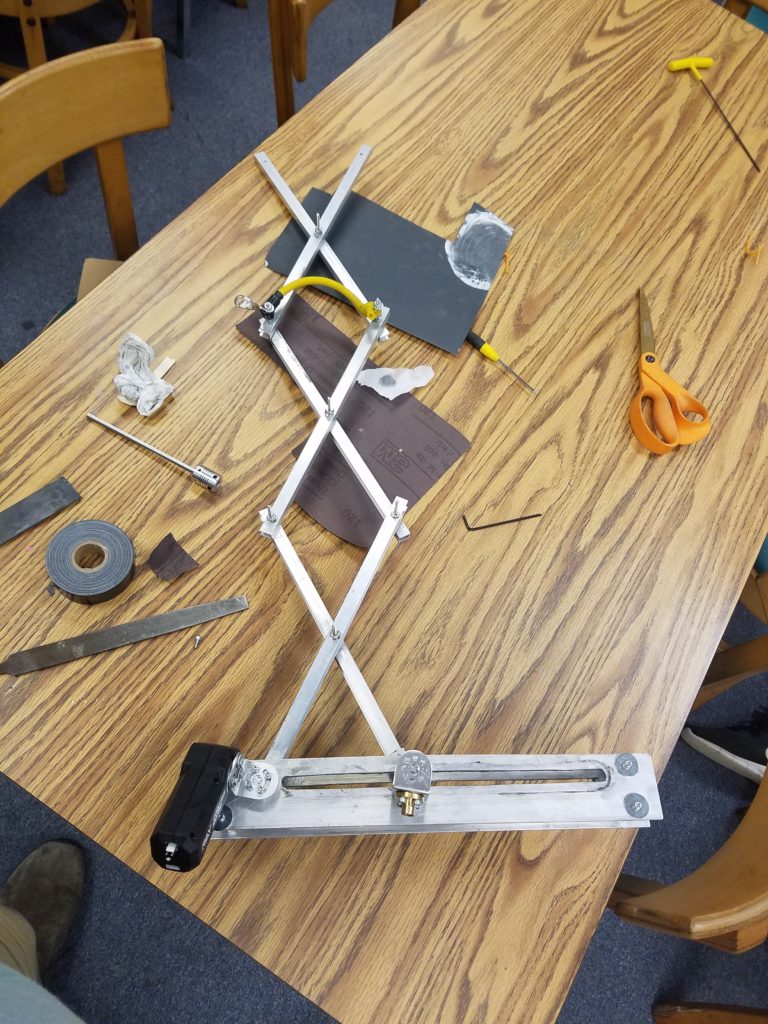

Our Relic Arm (v1)

The largest single thing we can do to score points on the field is to score the relic standing up in the farthest zone. Knowing this, we spent a lot of time working on a mechanism to score those points reliably. The first design we tried was inspired by a scissor lift. The mechanism was almost identical, but the entire thing was rotated horizontally instead of vertically. We liked that we would be able to get a very long arm length from a compact mechanism. The fact that it could be driven by a single motor was also a plus. We had to dump this idea because the weight on the end of the arm caused it to bend in a way that was impossible to use.

The largest single thing we can do to score points on the field is to score the relic standing up in the farthest zone. Knowing this, we spent a lot of time working on a mechanism to score those points reliably. The first design we tried was inspired by a scissor lift. The mechanism was almost identical, but the entire thing was rotated horizontally instead of vertically. We liked that we would be able to get a very long arm length from a compact mechanism. The fact that it could be driven by a single motor was also a plus. We had to dump this idea because the weight on the end of the arm caused it to bend in a way that was impossible to use.

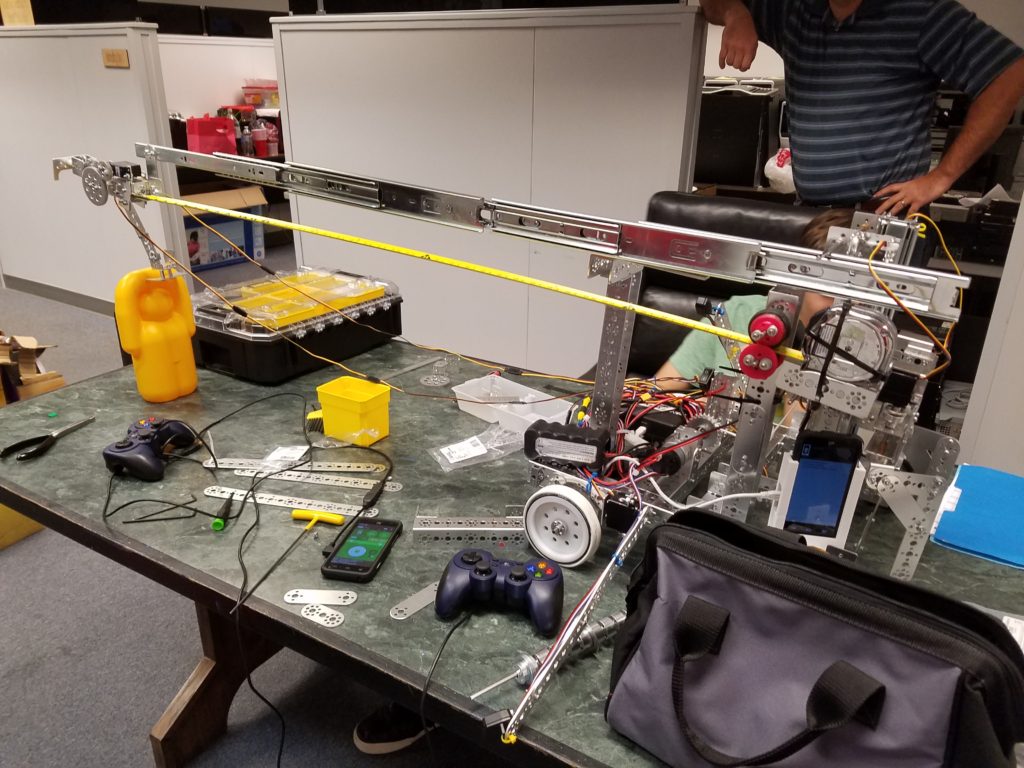

Relic Arm (v2)

For our second go at this mechanism, we took an entirely different approach. We decided that instead of trying to build our own mechanism from scratch, we would modify and adapt an existing one. We chose drawer slides because of their good length and high load capacity. Our mechanism uses two slides mounted to each other for over 3 feet of reach. The mechanism has almost no flex and is super reliable. There is very little friction which means it is smooth and fast for us to extend it. The slides are also super reliable. We have been able to score the relic almost every time with this contraption.

For our second go at this mechanism, we took an entirely different approach. We decided that instead of trying to build our own mechanism from scratch, we would modify and adapt an existing one. We chose drawer slides because of their good length and high load capacity. Our mechanism uses two slides mounted to each other for over 3 feet of reach. The mechanism has almost no flex and is super reliable. There is very little friction which means it is smooth and fast for us to extend it. The slides are also super reliable. We have been able to score the relic almost every time with this contraption.